Precision Surface-Treated Metal Parts

Advanced CNC machining combined with specialized surface treatment processes delivering enhanced corrosion resistance, wear protection, and aesthetic excellence. Export quality standards serving EU/US markets with OEM/ODM capabilities and stable supply chain.

- ✓ Export to EU/US Markets | OEM/ODM | Stable Supply

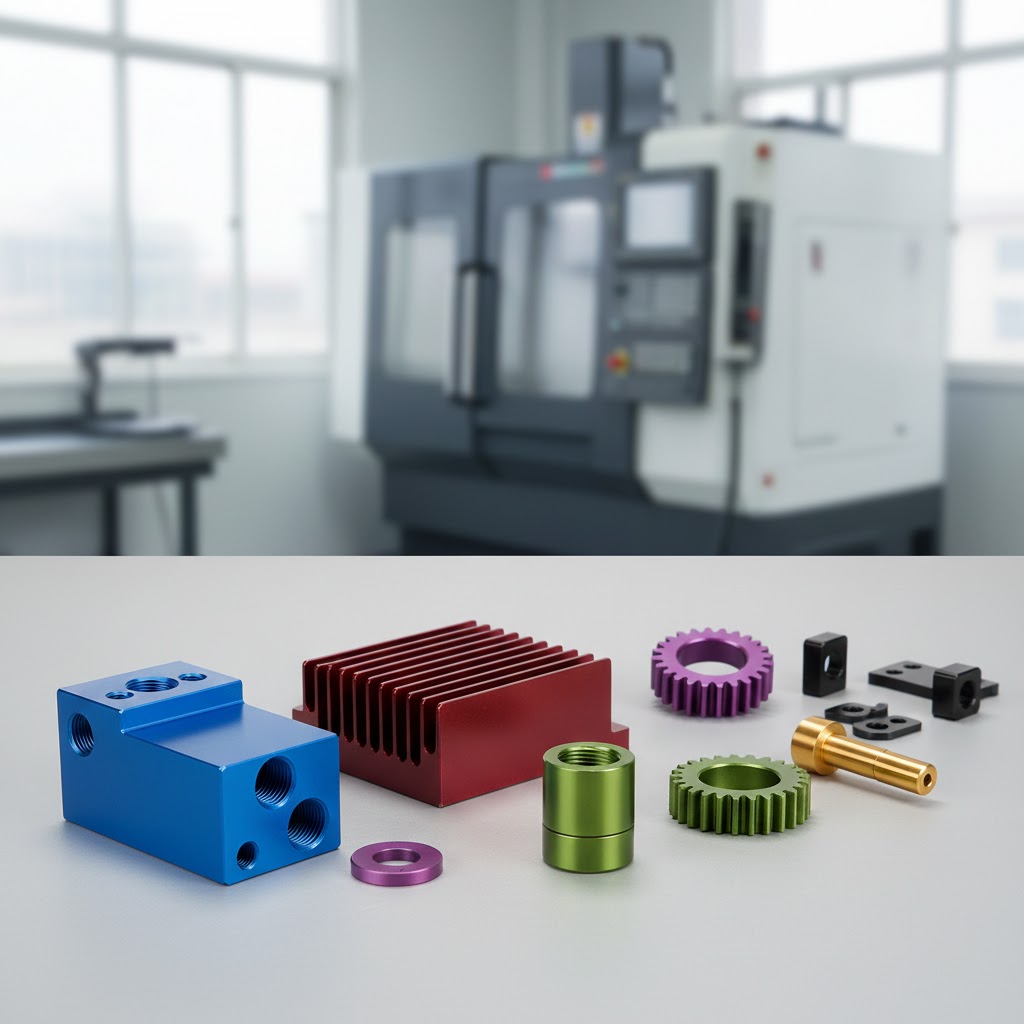

- ✓ Multiple Surface Treatments: Anodizing, Plating, Coating, Polishing

- ✓ Precision CNC + Coating Thickness & Corrosion Resistance Control

Critical Challenges in Surface-Treated Metal Parts Manufacturing

Surface-treated metal components face unique technical challenges requiring precise control throughout machining and finishing processes.

Machining & Surface Stability

Precision CNC tolerances must be maintained while ensuring consistent surface quality across production batches.

Environmental Performance

Different applications demand specific corrosion and wear resistance levels requiring tailored treatment selection.

Complex Process Selection

Choosing optimal surface treatment from anodizing, plating, coating options requires material and application expertise.

Batch Consistency Control

Maintaining coating thickness, color uniformity, and finish quality across thousands of parts for assembly reliability.

Surface Treatment Solutions by Application Environment

Specialized surface treatment strategies optimized for specific operating environments and performance requirements.

Corrosion-Critical Components

Enhanced protection for outdoor and energy equipment through specialized anodizing and multi-layer coating systems.

Assembly Precision Parts

Controlled coating thickness maintains tight assembly tolerances for industrial automation and robotic systems.

Decorative & Tactile Components

Premium aesthetic finishes with consistent color and texture for consumer appliances and furniture applications.

High-Strength Load-Bearing Parts

Heat treatment and wear-resistant coatings enhance mechanical performance for structural machinery components.

Surface-Treated Metal Parts Product Series

Comprehensive product range categorized by machining process and surface treatment type for diverse industrial applications.

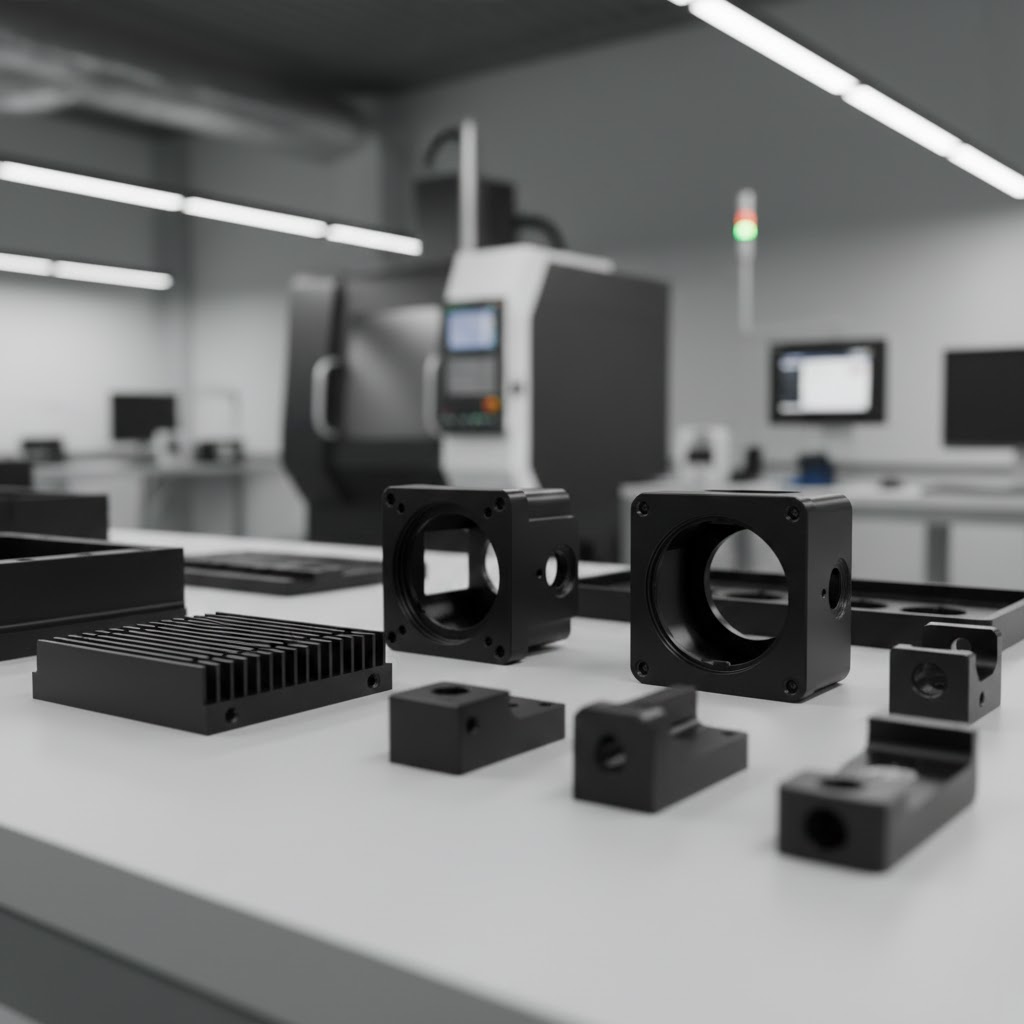

CNC Precision Metal Parts

Multi-axis machined components ready for surface treatment with tight tolerances.

Precision Thread/Hole Parts

Complex threading and hole operations maintaining dimensional accuracy post-treatment.

Anodized Components

Oxidation and anodizing treatments providing corrosion resistance and aesthetic appeal.

Nickel/Zinc Plated Parts

Electroplating processes delivering wear resistance and environmental protection.

Spray/Powder Coated Parts

Spray coating and powder coating for durable, attractive finishes across materials.

Technical Capabilities & Workflow Process

Systematic manufacturing workflow ensures quality control at every stage from design through final packaging and delivery.

Design Review

DFM analysis and surface treatment recommendation based on application requirements.

CNC Machining

3/4/5-axis precision machining with SPC control and in-process measurement.

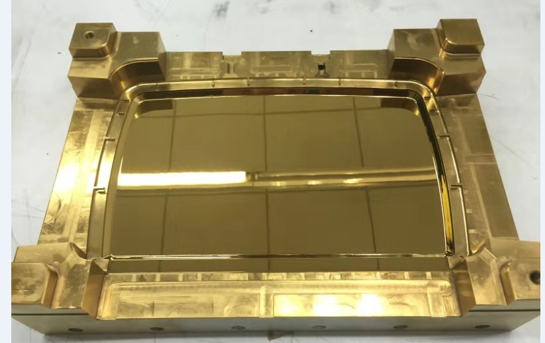

Surface Treatment

Anodizing, plating, or coating with controlled thickness and finish quality.

Quality Inspection

CMM dimensional verification, coating thickness testing, corrosion resistance validation.

Clean & Package

Standardized cleaning, protective packaging, and documentation for delivery.

Surface Treatment Manufacturing Success Stories

Structured case studies demonstrating our engineering capability to solve complex surface treatment challenges with measurable results.

Electronics

Electronics

Consumer Electronics Manufacturer

Aluminum housing requiring Type II anodizing with precise color matching across production batches. Process optimization achieved consistent Ra 0.8 finish quality.

Result: 99.5% color match consistency, zero customer returns for appearance

Automation

Automation

Industrial Automation OEM

Precision brackets with hard anodizing requiring controlled coating thickness to maintain ±0.02mm assembly tolerance. Engineering collaboration optimized masking strategy.

Result: Assembly fit maintained, 500hr salt spray test passed

Medical

Medical

Medical Device Manufacturer

Stainless steel components requiring electropolishing and passivation for biocompatibility. Validation testing confirmed compliance with ISO 13485 standards.

Result: FDA documentation approved, ongoing production partnership

Frequently Asked Questions

How do different surface treatments affect corrosion resistance?

Anodizing creates a protective oxide layer ideal for aluminum parts in outdoor environments. Zinc plating offers economical corrosion protection for steel. Nickel plating provides superior wear and corrosion resistance. PVD coatings deliver exceptional hardness and chemical resistance. We recommend treatments based on specific environmental conditions and performance requirements.

What precision levels can your CNC machining achieve before surface treatment?

Our CNC machining centers achieve ±0.01mm tolerances with surface finishes to Ra 1.6. We account for coating thickness in machining dimensions to ensure final parts meet assembly tolerances post-treatment. Critical features can be masked during treatment to preserve machined accuracy.

Do you provide PPAP documentation and inspection reports?

Yes, complete PPAP packages include dimensional reports, material certifications, coating thickness measurements, salt spray test results, and surface finish analysis. We provide full traceability documentation meeting automotive and medical device industry standards.

What are typical lead times for samples versus production quantities?

Sample parts with surface treatment typically require 2-3 weeks including machining, treatment, and testing. Production quantities depend on volume and complexity but generally range from 3-6 weeks. Expedited options available for urgent requirements with advance coordination.

Global Cooperation & Delivery Capabilities

Proven international export experience with comprehensive logistics coordination and engineering support for global customers.

Europe

Germany, United Kingdom, Belgium

Americas

United States

Asia-Pacific

Japan, Thailand, New Zealand