Precision Consumer Product Molds

Factory-direct mold manufacturing in China delivering OEM/ODM solutions for consumer electronics, home appliances, and lifestyle products. We combine advanced engineering with cost-effective production to bring your consumer product designs to market faster.

- ✓ Free DFM analysis and mold design optimization

- ✓ Multi-cavity, thin-wall, and overmolding capabilities

- ✓ Fast turnaround with complete quality documentation

Consumer Product Mold Solutions

Specialized mold engineering for consumer products requiring premium aesthetics, functional performance, and high-volume manufacturing efficiency.

Consumer Electronics

Precision molds for smartphones, tablets, wearables, and audio devices with Class A finishes, thin-wall construction, and multi-material integration.

Home Appliances

Large-part molding for kitchen appliances, climate control, and cleaning equipment with heat-resistant materials and consistent quality.

Personal Care & Beauty

Premium molds for grooming tools and cosmetic packaging with mirror-finish surfaces, ergonomic design, and safe-touch materials.

Household & Storage

Durable molds for containers and organizers with food-safe compliance, efficient production, and reliable performance.

End-to-End Mold Development Services

Comprehensive service offering covering every phase from concept to production validation, ensuring design intent translates perfectly into manufacturable tooling.

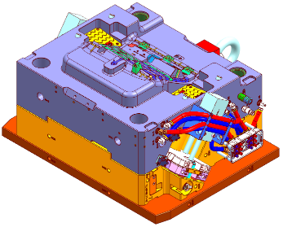

DFM Analysis & Design

Free design review and 3D mold engineering with CAD/CAE simulation to optimize manufacturability before tooling.

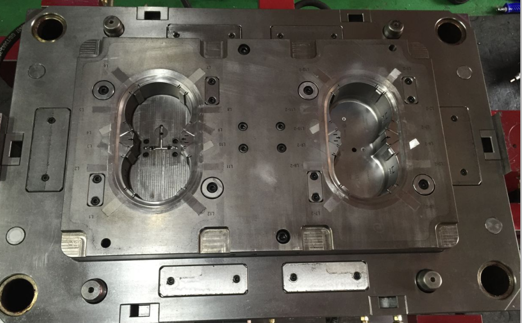

Precision Machining

Advanced CNC and EDM processing delivering micro-precision tolerances and mirror-finish surfaces for premium aesthetics.

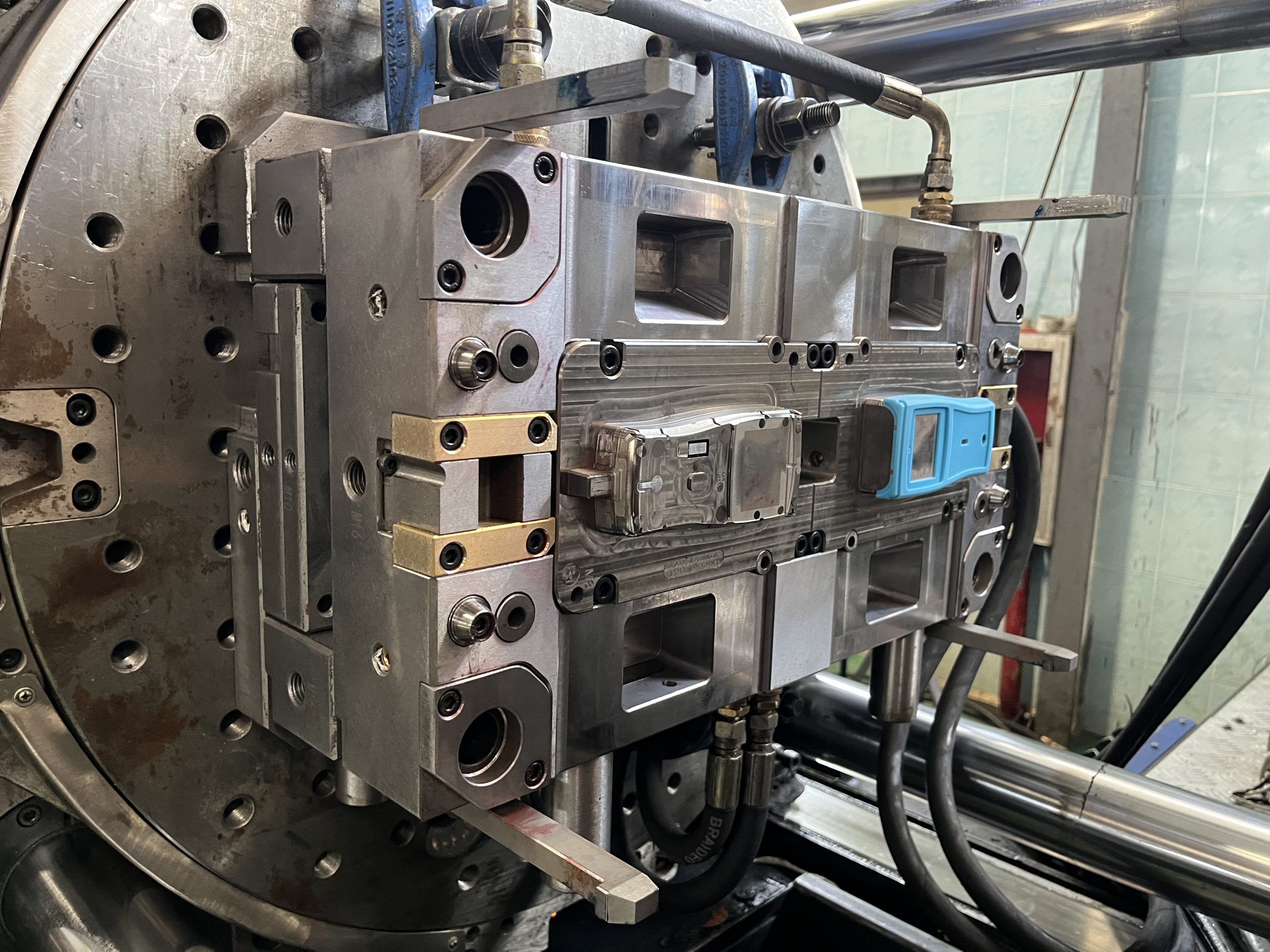

Trial & Validation

In-house molding presses for performance validation and process optimization before mold shipment.

Quality Documentation

Complete inspection reports and certifications with 24-hour quote response and fast turnaround options.

Advanced Molding Technologies

Specialized injection molding techniques enabling complex designs, reduced assembly operations, and improved product performance for consumer applications.

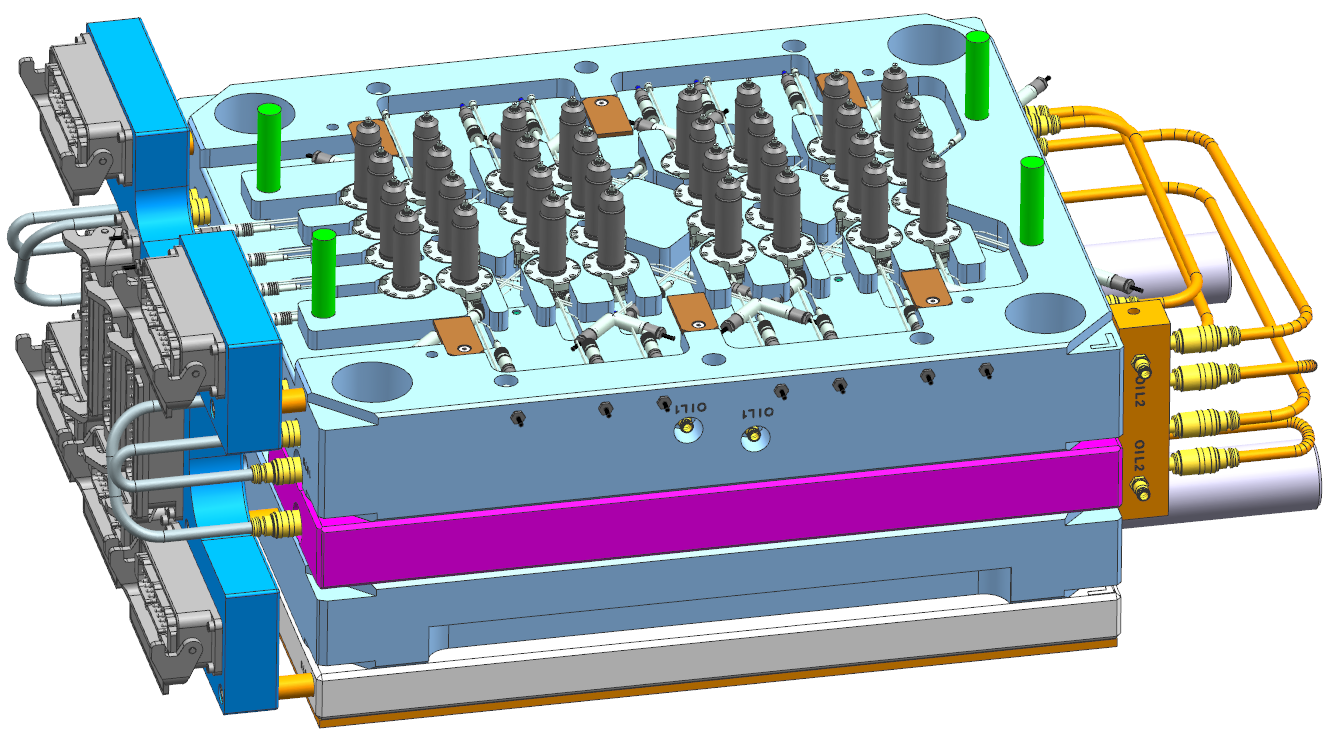

Multi-Cavity Molding

Balanced runner systems producing identical parts simultaneously for maximum productivity and tight dimensional consistency.

Overmolding / Insert

Multi-material combination and metal insert encapsulation creating ergonomic grips and premium interfaces without assembly.

Thin-Wall Molding

Specialized techniques achieving wall thickness below 1mm for lightweight compact designs while maintaining structural integrity.

LDPE / TPE / LSR

Soft-material processing for flexible components requiring biocompatibility, flexibility, and chemical resistance.