Precision Mold & High-Tolerance CNC Machining Parts

Spare Parts, CNC & Tooling Production with engineering precision. We deliver high-accuracy metal components, precision mold inserts, and custom CNC parts for demanding applications requiring tight tolerances and consistent quality.

- ✓ High Precision | High Stability | Fast Response

- ✓ OEM/ODM Support with Complete Engineering Control

- ✓ Multi-Axis CNC Capabilities for Complex Geometries

Why Precision CNC & Mold Tooling Demands Specialized Expertise

High-tolerance CNC parts and precision mold components face unique engineering challenges. Understanding these critical requirements prevents costly mistakes and production delays.

Extreme Precision Requirements

Tolerances down to ±0.005mm required for mating parts and critical dimensions in assemblies.

Hardware & Mold Fitting

Zero-tolerance for mating errors between metal components and mold cavities requiring perfect assembly.

Complex Material Machining

Diverse materials including hardened steel, aluminum alloys, stainless steel, and copper requiring specialized tooling.

Batch-to-Batch Consistency

Maintaining dimensional consistency across production runs for interchangeable parts and tooling components.

Comprehensive CNC & Tooling Manufacturing Services

Result-focused services ensuring precision parts meet exact specifications from design review through final inspection and delivery.

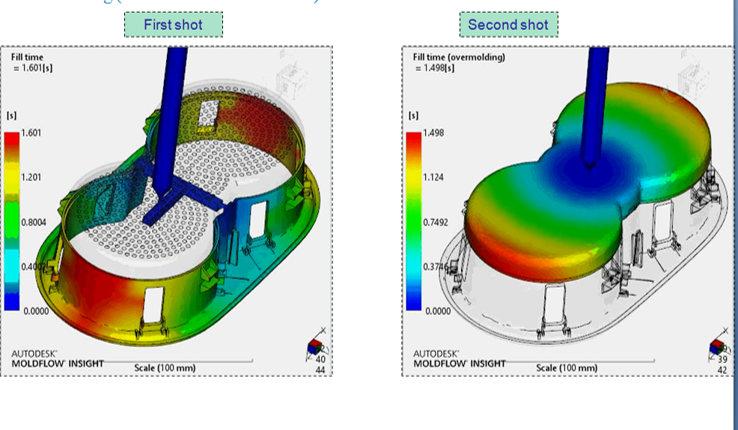

3D/2D Drawing DFM Assessment

Engineering review optimizes designs for manufacturability, identifies potential issues, and recommends cost-effective alternatives before production.

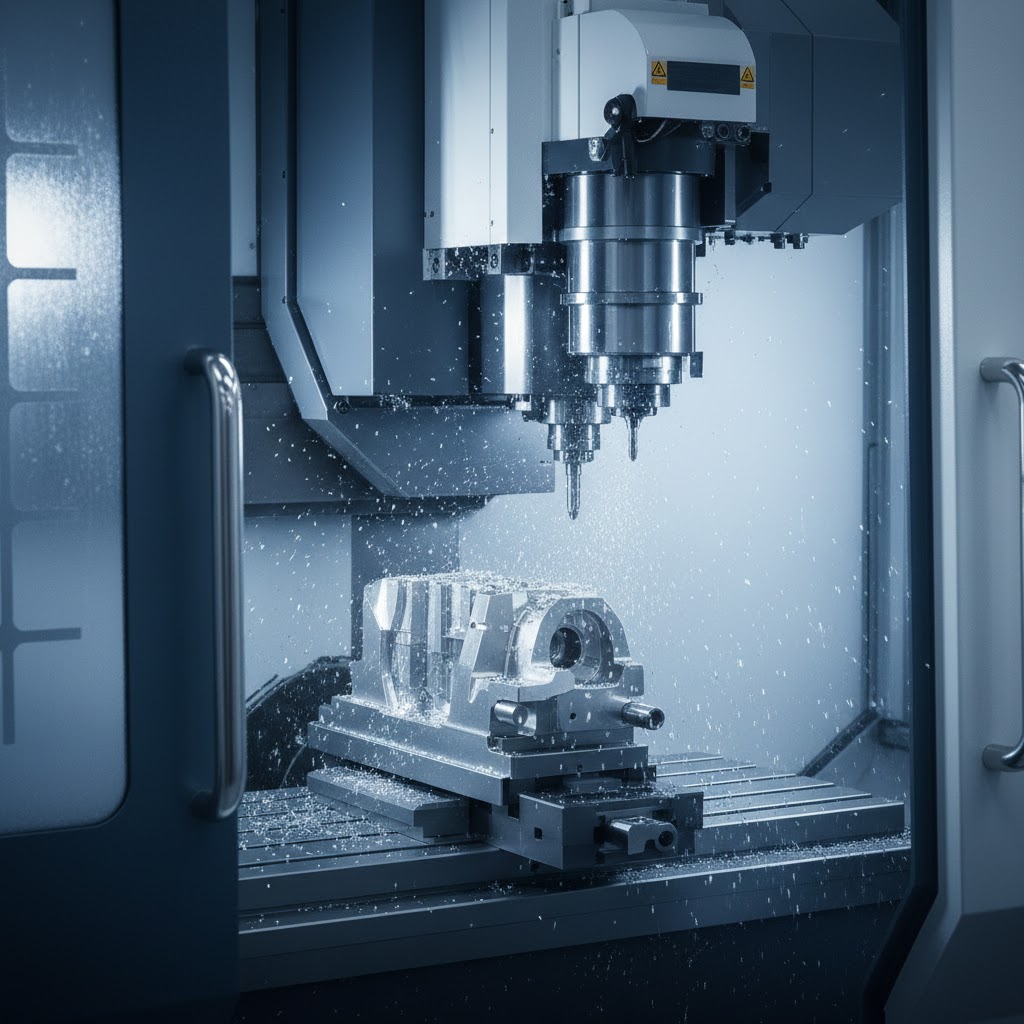

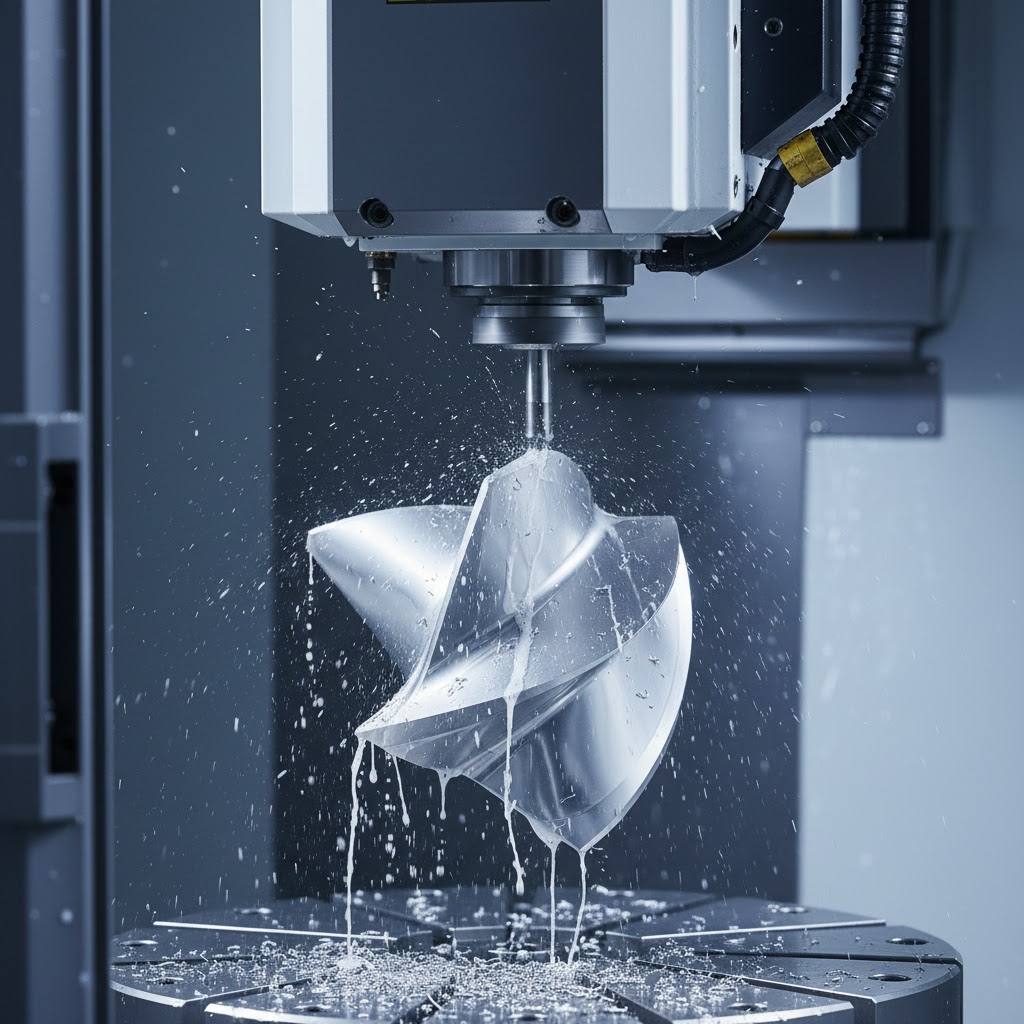

High-Precision CNC Machining

Multi-axis machining for aluminum, steel, stainless steel, and copper with tolerances to ±0.005mm using advanced CNC centers.

Full Engineering Communication

Direct access to engineering team throughout project lifecycle ensuring technical clarity and rapid problem resolution.

Specialized CNC & Tooling Solutions by Application

Tailored manufacturing solutions addressing specific technical requirements across diverse industrial applications and component types.

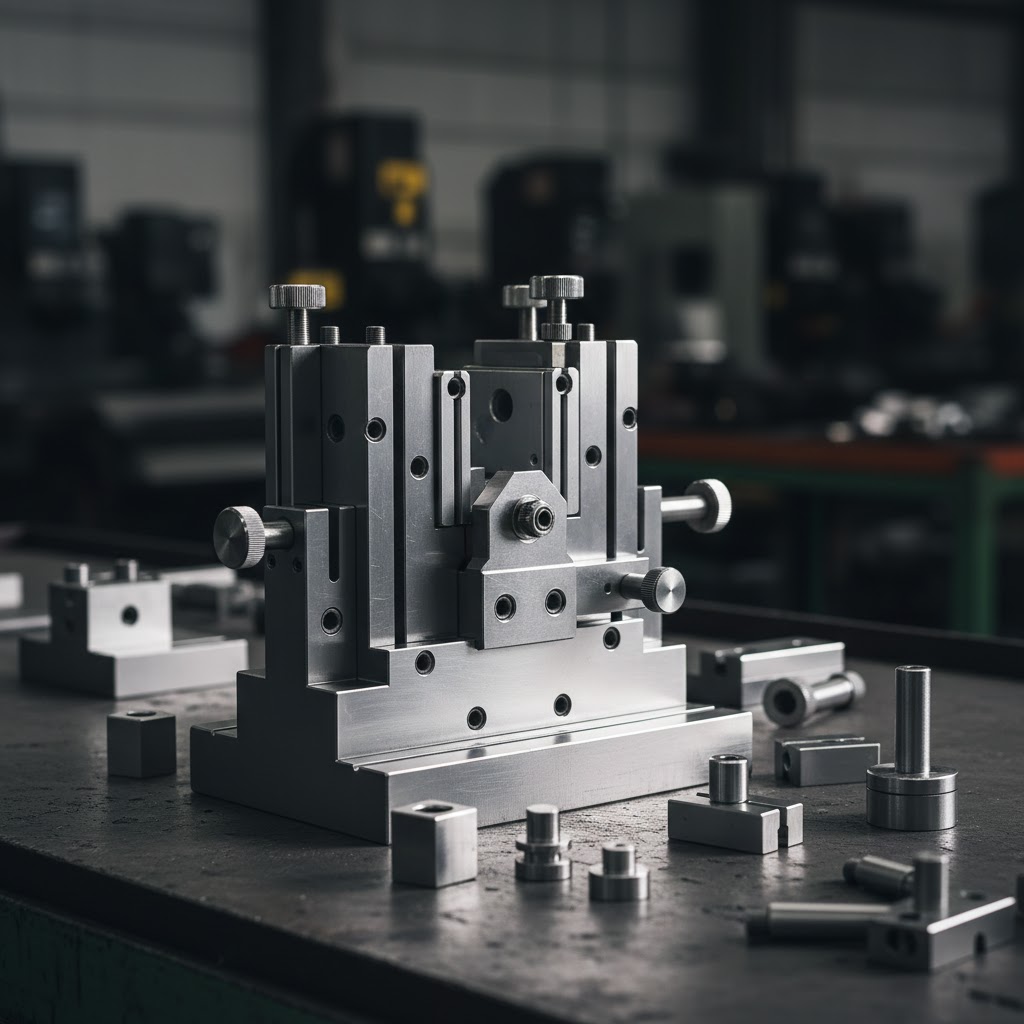

Hardware Fittings & Jigs

Custom fixtures, assembly jigs, and precision hardware fittings with repeatable accuracy for manufacturing operations.

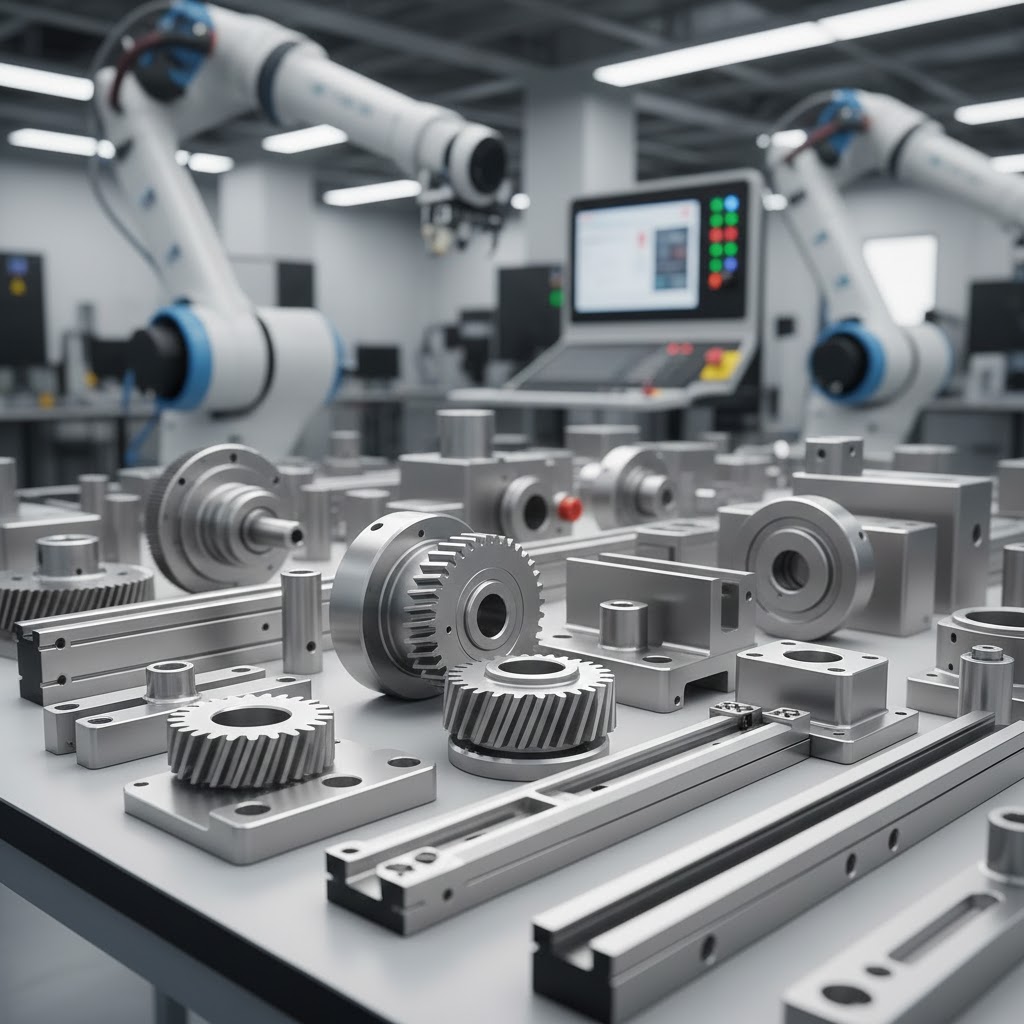

Automation & Robotics

Precision components for automated systems requiring tight tolerances and reliable performance under continuous operation.

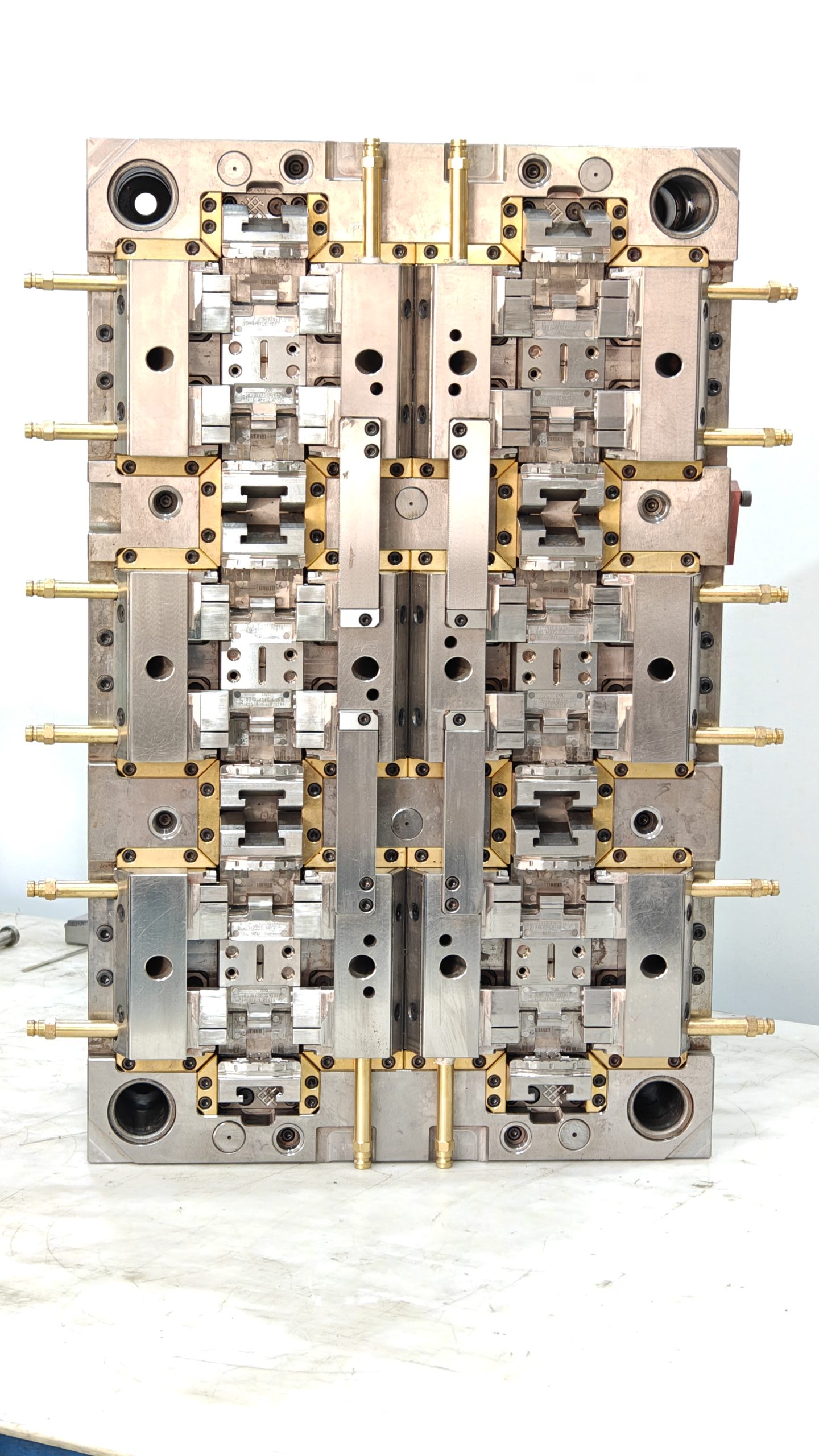

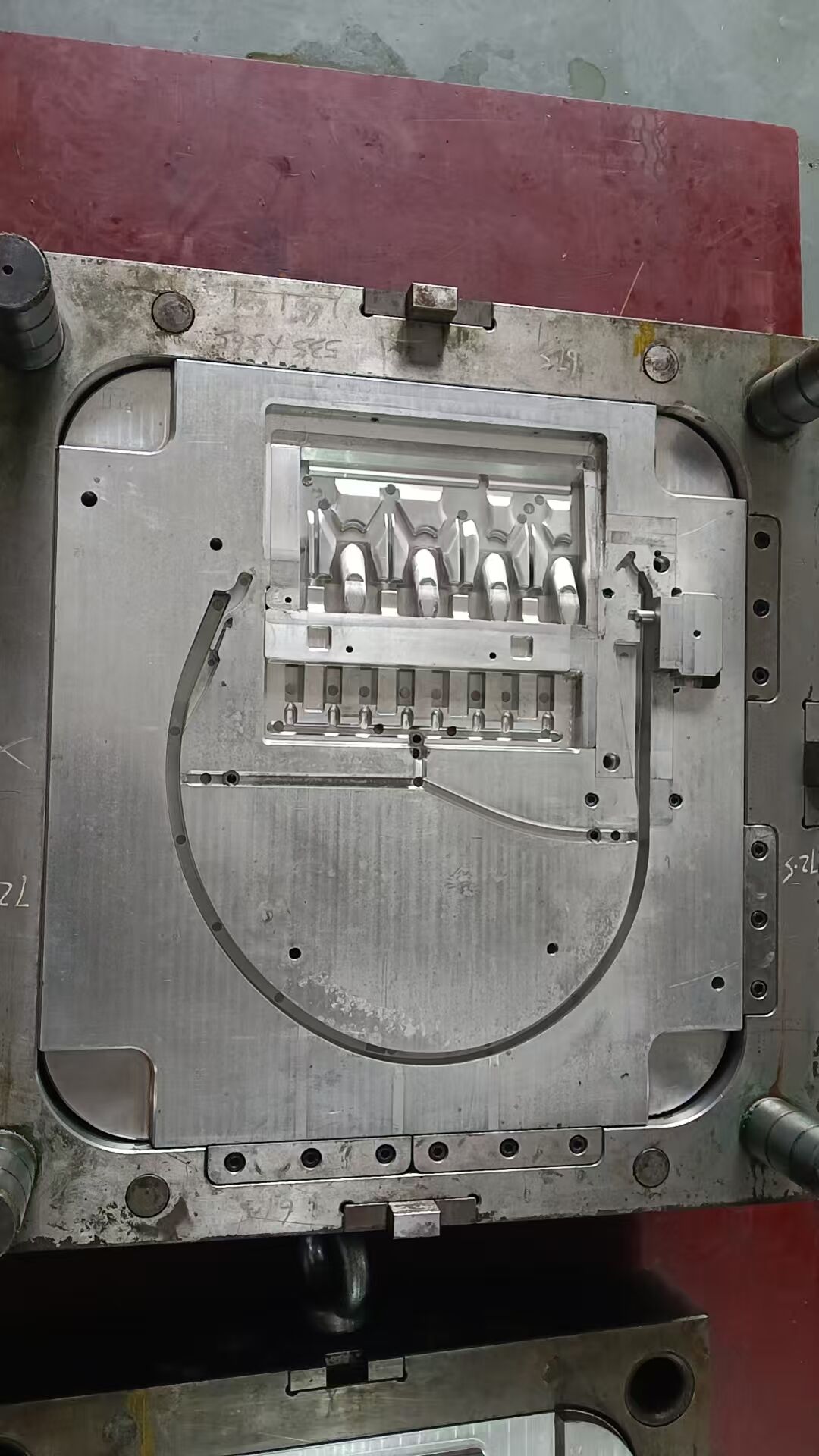

Precision Mold Inserts

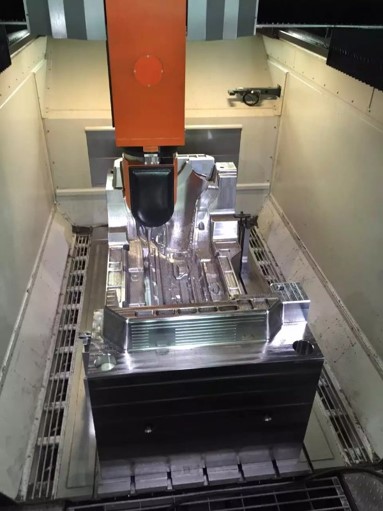

Hardened steel inserts and cavity components with mirror finishes and critical dimensional accuracy for mold assemblies.

Prototypes & Production

Flexible capacity handling prototype quantities through high-volume production with consistent quality and fast turnaround.

CNC & Tooling Parts Product Series

Comprehensive range of precision-machined components categorized by application, material, and machining characteristics.

CNC Machined Metal Parts

Precision metal components in aluminum, steel, and stainless steel for industrial applications.

Tolerance: ±0.01mm | Surface: Ra 0.8

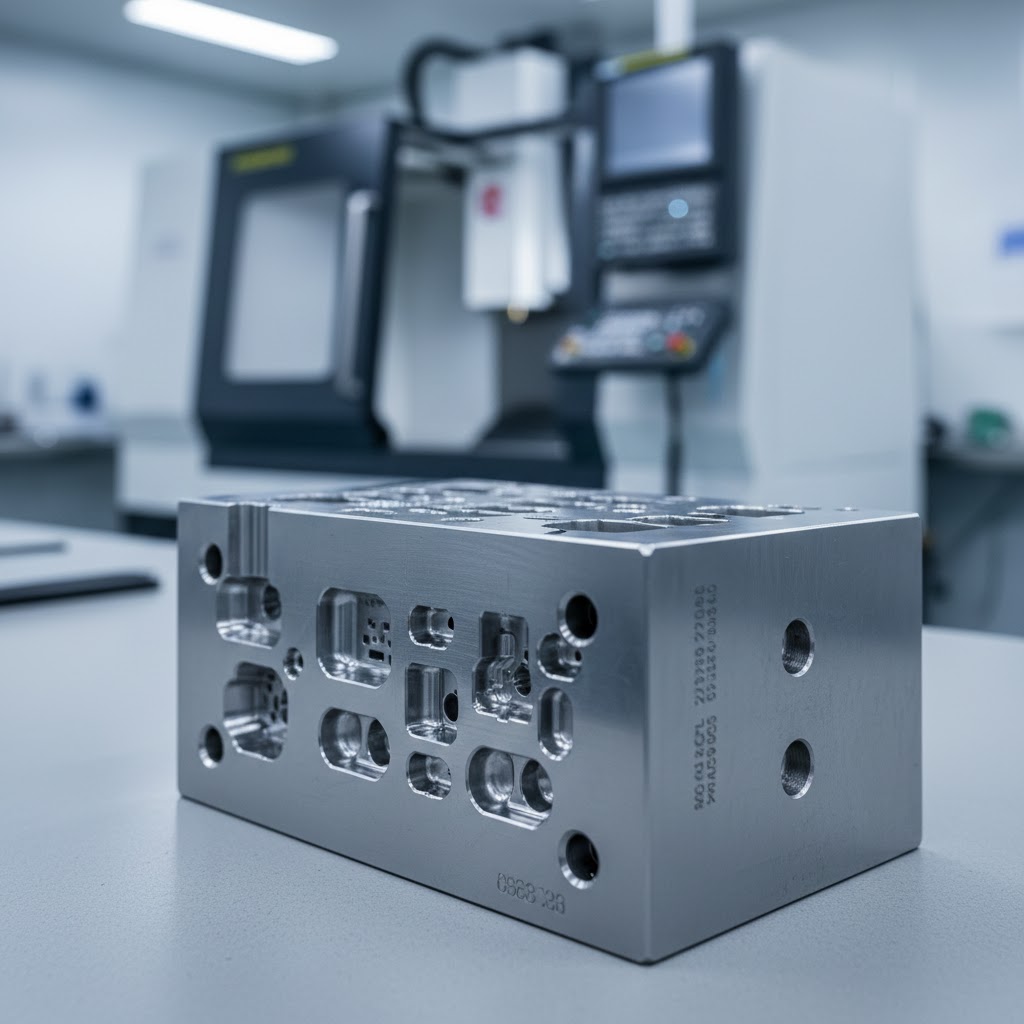

Precision Mold Tooling Parts

Hardened inserts, cavity components, and fixtures for injection mold assemblies.

Tolerance: ±0.005mm | Hardness: HRC 50-58

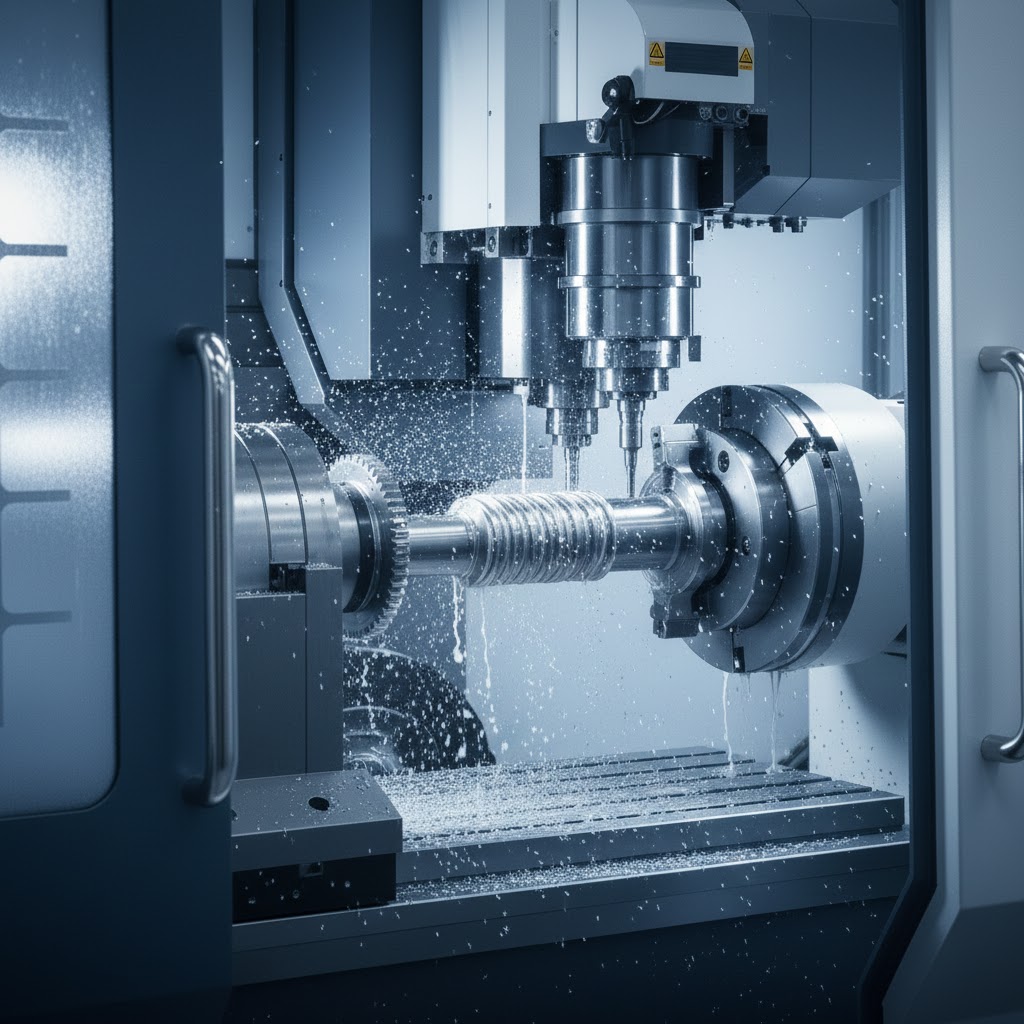

High-Tolerance Turned & Milled

Complex geometries combining turning and milling operations for shafts, housings, and brackets.

Tolerance: ±0.01mm | Concentricity: 0.005mm

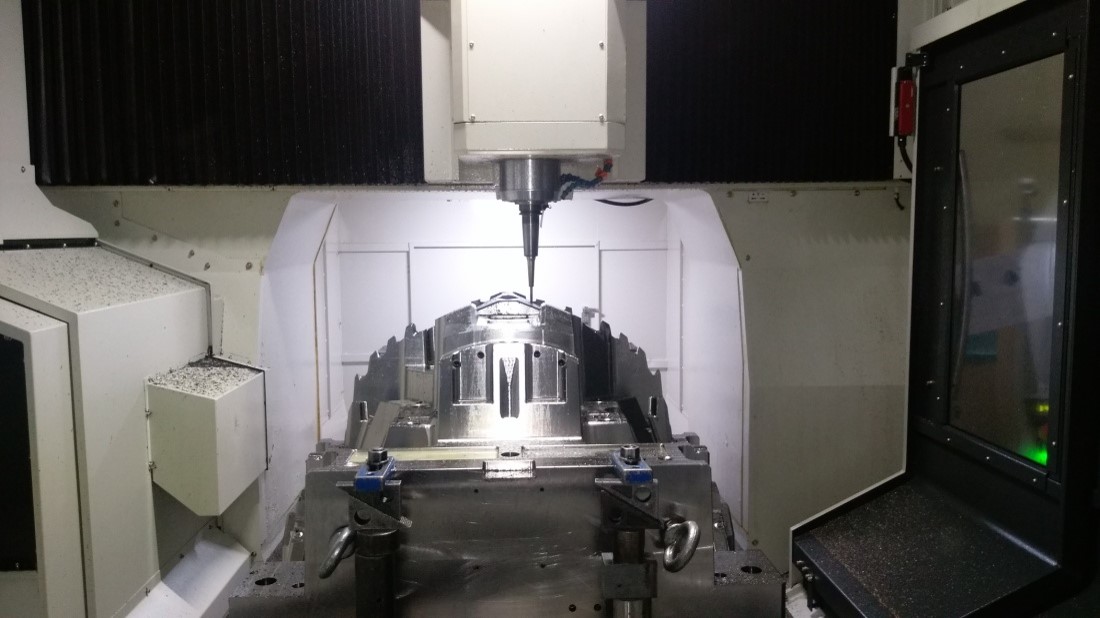

Multi-Axis CNC Components

Complex 3D contours requiring 4/5-axis simultaneous machining for aerospace and medical parts.

Tolerance: ±0.005mm | Surface: Ra 0.4

CNC Machining & Mold Manufacturing Capabilities

Advanced engineering capabilities supported by state-of-the-art equipment and systematic quality control throughout every process stage.

3/4/5-Axis CNC Centers

Advanced machining centers handling complex geometries with simultaneous multi-axis movements for optimal precision.

Precision Grinding & EDM

Surface and cylindrical grinding, wire EDM, and sinker EDM for hardened materials and intricate details.

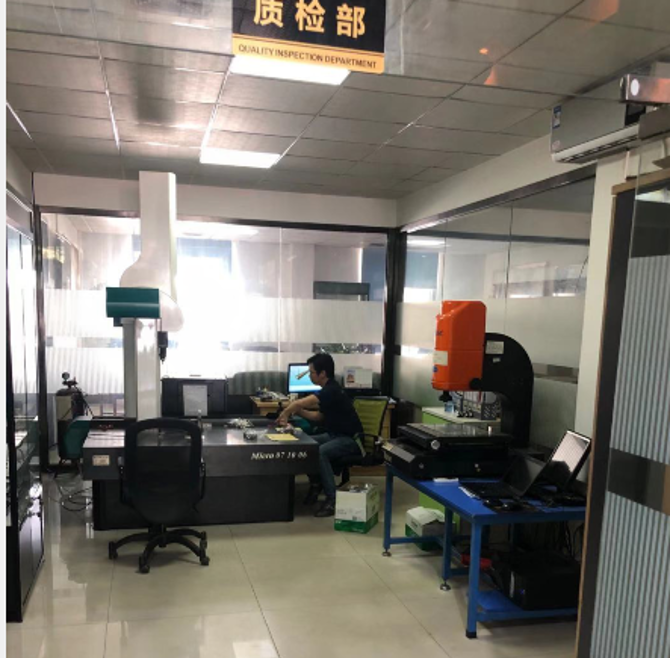

CMM & Measurement Systems

Comprehensive inspection with CMM, optical comparators, and coordinate measuring for dimensional verification.

CAD/CAM/CAE Integration

Advanced software for design optimization, machining simulation, and collaborative engineering with mold design.

Our Competitive Advantages in Precision Manufacturing

Strategic advantages combining direct factory access, responsive engineering support, and proven international delivery standards.

Factory Direct Supply

No middlemen. Direct manufacturing access reduces costs and improves communication efficiency.

24-Hour Technical Response

Engineering team provides rapid feedback on technical questions and design modifications.

Full Engineering Participation

Technical team engaged throughout process from design review to final validation and delivery.

International Standards

Proven delivery experience meeting European and American quality and documentation requirements.

Success Stories in Precision CNC & Tooling Manufacturing

Structured case examples demonstrating our engineering capability to solve complex precision manufacturing challenges with measurable results.

Automation

Automation

Robotics Component Manufacturer

Precision shaft requiring ±0.003mm concentricity and Ra 0.4 surface finish. Multi-axis turning with in-process monitoring achieved specifications.

Result: 100% dimensional compliance, zero rejects across 5,000 units

Tooling

Tooling

Medical Device Mold Insert

Complex cavity geometry in hardened H13 steel requiring mirror finish and ±0.005mm tolerance. Wire EDM and precision grinding achieved Class 1 surface.

Result: First-article approval, 50,000+ cavity cycles without wear

Aerospace

Aerospace

Aerospace Fixture Components

Titanium alloy parts with complex 3D contours requiring 5-axis simultaneous machining. Advanced CAM programming and toolpath optimization reduced cycle time.

Result: 30% faster delivery, complete PPAP documentation compliance

Frequently Asked Questions

What precision levels can your CNC machining achieve?

Our multi-axis CNC centers routinely achieve ±0.005mm tolerances with surface finishes to Ra 0.4. For critical applications, we can hold ±0.003mm with specialized fixturing and temperature-controlled machining.

How do you control mold and machined part assembly tolerances?

We use coordinate-based machining with CMM verification for all mating features. Assembly tolerance stack-up analysis during DFM phase identifies critical dimensions requiring tighter control. In-process measurement ensures dimensional consistency.

Do you provide PPAP documentation and inspection reports?

Yes, complete PPAP packages including dimensional reports, material certifications, surface finish measurements, and first article inspection are standard. CMM reports with measured points and 3D deviation analysis available upon request.

How do you price small batch versus large volume production?

Prototype and small batch pricing includes setup optimization and first-article validation. Volume pricing reflects reduced setup allocation and process refinement. We provide transparent breakdowns showing unit cost evolution across quantity tiers.