Full-Service Solution

BMC Insulator Manufacturing

We provide a complete solution for BMC insulator manufacturing—from mold design to finished product shipping. Since 2008, we have collaborated with our German partner, Schmidt Kunststoffverarbeitung Emsbüren GmbH & Co. KG—initially on injection molds. In 2016, we began producing insulators for their needs, and today we proudly serve as their official production base in China. Our close partnership ensures that every product meets the same high standards as those manufactured in Germany.

To meet the growing demand for BMC molded parts, we established a new factory in Hubei, allowing us to handle orders with specific technical requirements while maintaining precision, efficiency, and reliability

- German Expertise – Continuous technical support from our German partner since day one.

- End-to-End Service – From design to production, assembly, and shipping.

- Custom Manufacturing – Flexible solutions tailored to specific requirements.

- High Standards – Manufactured to DIN EN 61439-1 and other international standards.

- Scalable Production – Large-scale capacity to meet increasing demand.

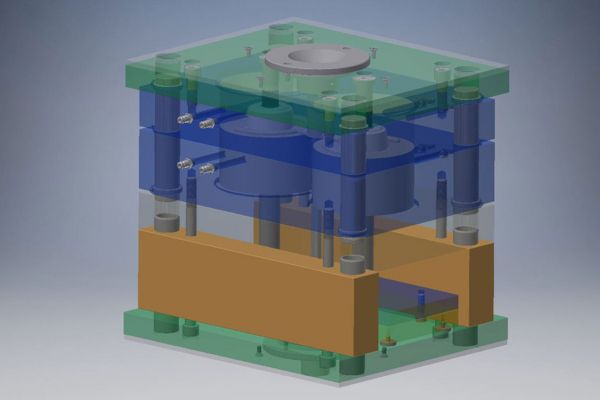

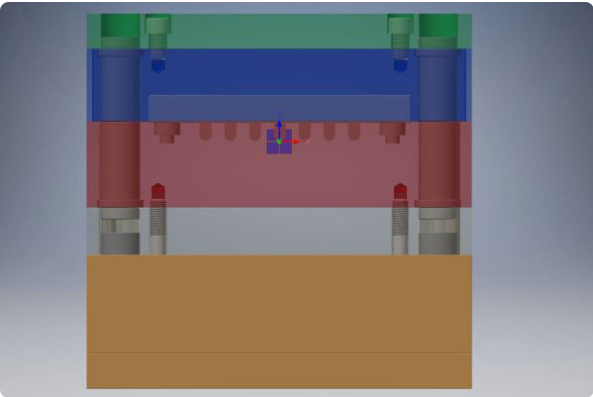

In-House Tool Making for Precision and Quality

Our in-house mold-making ensures the highest precision and reliability for BMC insulator production. With our advanced tool shop, we design and manufacture custom compression molds that meet strict quality standards. This allows us to guarantee consistency, durability, and cost-efficiency for every insulator we produce.

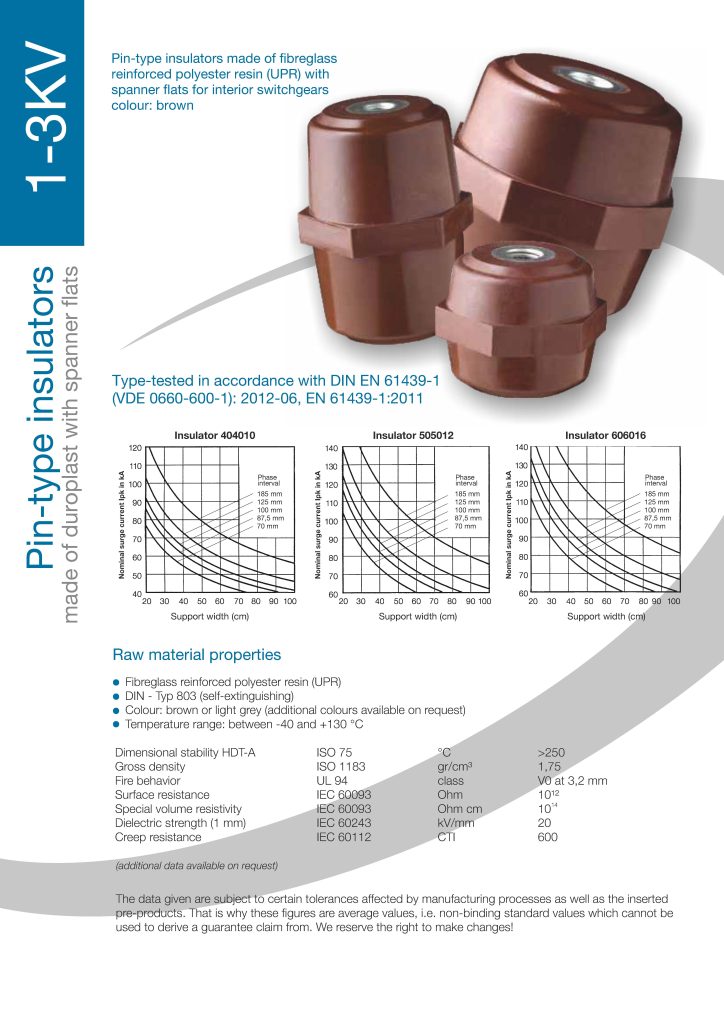

Product Features

✔ Type-tested according to DIN EN 61439-1 (VDE 0660-600-1): 2012-06 and EN 61439-1:2011

✔ Made of glass fiber-reinforced BMC with wrench flats

✔ Designed for indoor switchgear applications

✔ Available in brown (or custom colors upon request)

Raw material properties

- Base Material: Glass fiber-reinforced polyester resin (UP)

- Self-Extinguishing: Meets DIN Type 803

- Fire Resistance: UL 94 Class V0 at 3.2 mm

- Temperature range from -40 to +130 °C

- Color: brown or light gray (other colors on reque)

Note:The data we quote are subject to certain tolerances due to the manufacturing process and the primary materials used. They represent average values and are intended as non-binding guidelines, from which no warranty claims can be derived. We reserve the right to make changes.

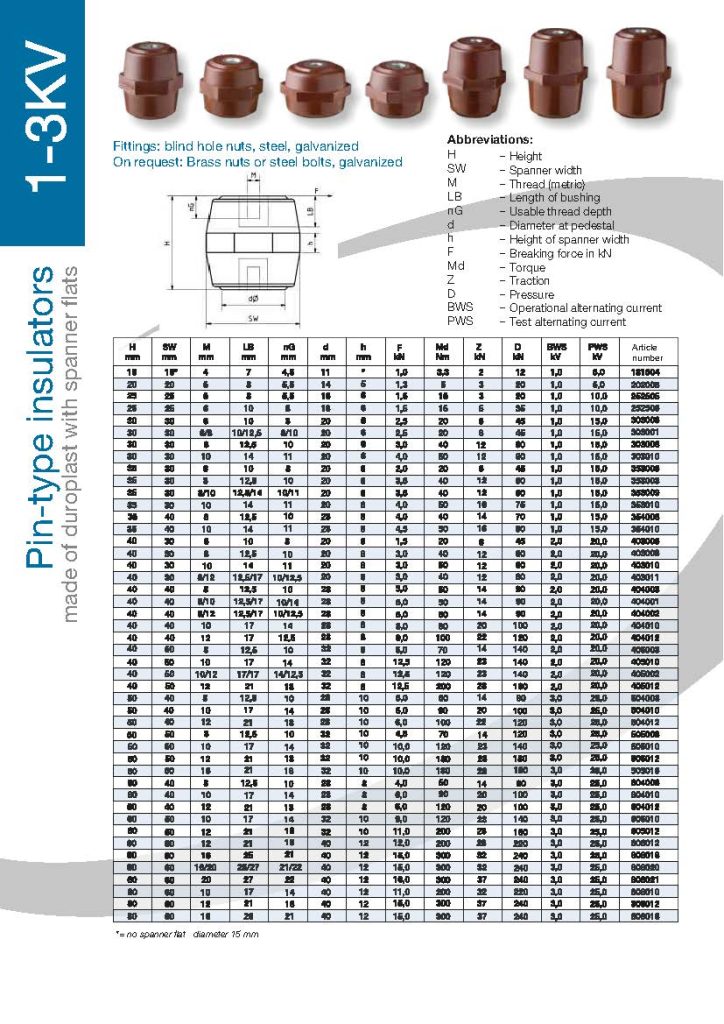

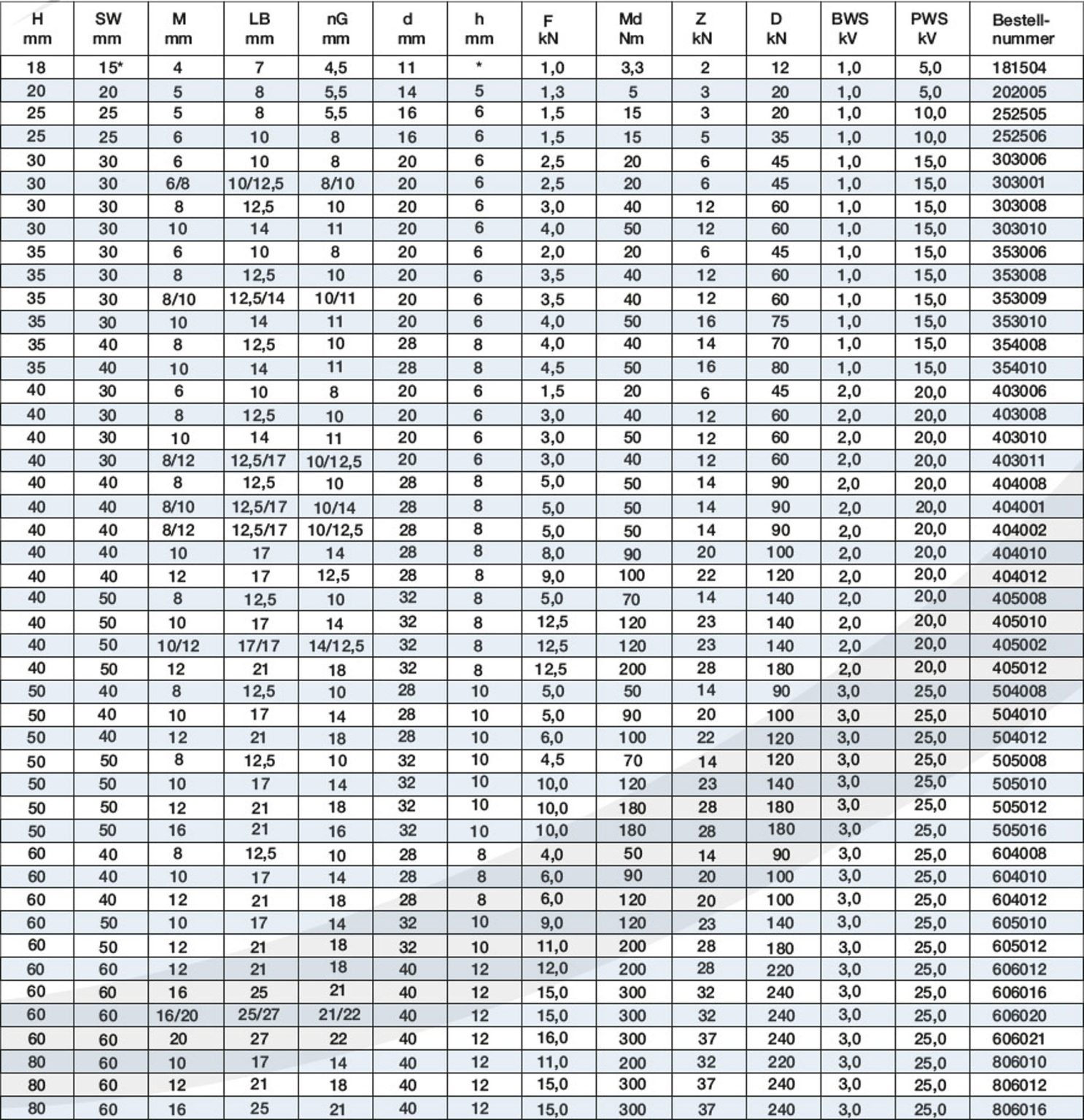

Product details

Standard Fittings: Blind nuts made of galvanized steel

Optional Fittings: Brass nuts or galvanized steel bolts available upon request

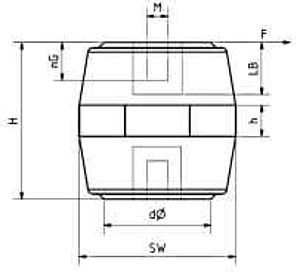

- H = height

- SW = Width across flats

- M = Thread (metric)

- LB = length of bushing

- nG = usable thread depth

- d = diameter at shoulder

- h = height SW

- F = wrap-around force

- Md = torque

- Z = tensile force

- D = compressive force

- BWS = Operating alternating stress

- PWS = test alternating stress

What We Produce

In addition to our standard product range, we also manufacture customer-specific technical injection molded parts tailored to your requirements.